Special grades CARB™ - series

™ S500 and ™ S500A - are high purity carbon black grades, specially designed for MRG. This products combine the highest degree of reinforcement, which is achieved due to high structure of the products, and exceptional purity, providing the final products with smooth surface. This grades have low grit content that makes it possible to produce high quality extruded profiles with very low surface undispersed particles . They are suitable for automotive extruded profiles, window profiles, seals and hydraulic hoses as well as for molded plastic profiles.

™ S500 and ™ S500A - are high purity carbon black grades, specially designed for MRG. This products combine the highest degree of reinforcement, which is achieved due to high structure of the products, and exceptional purity, providing the final products with smooth surface. This grades have low grit content that makes it possible to produce high quality extruded profiles with very low surface undispersed particles . They are suitable for automotive extruded profiles, window profiles, seals and hydraulic hoses as well as for molded plastic profiles.

™ S800 - is a purity carbon black with higher dispersion level as compared to standard carbon black grades. ™ S800 demonstrates excellent dispersion in compounds, high resistivity preventing rubber compounds from premature electrochemical destruction. It imparts high resilience and surface smoothness for rubber goods. ™ S800 is suitable for low viscosity porous rubber profiles, recommended for using in the production of radiator hoses to prevent electrochemical destruction, in engine suspension and driving belts where low hysteresis is required.

™ S800 - is a purity carbon black with higher dispersion level as compared to standard carbon black grades. ™ S800 demonstrates excellent dispersion in compounds, high resistivity preventing rubber compounds from premature electrochemical destruction. It imparts high resilience and surface smoothness for rubber goods. ™ S800 is suitable for low viscosity porous rubber profiles, recommended for using in the production of radiator hoses to prevent electrochemical destruction, in engine suspension and driving belts where low hysteresis is required.

™ S810 - provides high elongation and resilience as well as low compression set. Rubber items containing ™ S810 are characterized by good resilience and smooth surface. It is ideally suitable for viscosity porous rubber profiles manufacturing. ™ S810 is recommended for using in the production of radiator hoses to prevent electrochemical destruction. The product is also used in the production of rubber goods, footwear, inner tubes, tire insulting layers, shock absorbers.

™ S810 - provides high elongation and resilience as well as low compression set. Rubber items containing ™ S810 are characterized by good resilience and smooth surface. It is ideally suitable for viscosity porous rubber profiles manufacturing. ™ S810 is recommended for using in the production of radiator hoses to prevent electrochemical destruction. The product is also used in the production of rubber goods, footwear, inner tubes, tire insulting layers, shock absorbers.

™ S820 - easy to disperse carbon black with high level of distribution in polymers due to low surface area and high structure. Rubber products from compounds filled with ™ S820 improves rubber compounds processing properties and decreases compression set. Easiness and high quality of dispersibility make ™ S820 ideal for extruded rubber product applications where smooth surface appearance and high elasticity are desired..

™ S820 - easy to disperse carbon black with high level of distribution in polymers due to low surface area and high structure. Rubber products from compounds filled with ™ S820 improves rubber compounds processing properties and decreases compression set. Easiness and high quality of dispersibility make ™ S820 ideal for extruded rubber product applications where smooth surface appearance and high elasticity are desired..

Conductive line:

™ C40 - is a high clean carbon black with low content of sulfur, ash and grit, which allows to achieve excellent dispersion, smoothness of compound’s surface and necessary conductive properties. ™ C40 is suitable for insulation shield in medium voltage power cables, providing it with improved life expectancy.

™ C40 - is a high clean carbon black with low content of sulfur, ash and grit, which allows to achieve excellent dispersion, smoothness of compound’s surface and necessary conductive properties. ™ C40 is suitable for insulation shield in medium voltage power cables, providing it with improved life expectancy.

™ C140 - is a unique conductive carbon black grade with good coloring ability. Despite the high surface area, it has average reinforcing properties. Specifically developed surface area coupled with high structure of carbon black provides good electrical conductivity for various manufactured products: rubbers, cables and synthetic fibers.

™ C140 - is a unique conductive carbon black grade with good coloring ability. Despite the high surface area, it has average reinforcing properties. Specifically developed surface area coupled with high structure of carbon black provides good electrical conductivity for various manufactured products: rubbers, cables and synthetic fibers.

™ CH85 - is characterized by high absorption properties and structure providing increased physical and mechanical characteristics as well as low volume resistivity of rubber compounds. It is used in the production of power cables/wire jacketing, conveyor belts, driving belts, antistatic floor coverings in medical establishments.

™ CH85 - is characterized by high absorption properties and structure providing increased physical and mechanical characteristics as well as low volume resistivity of rubber compounds. It is used in the production of power cables/wire jacketing, conveyor belts, driving belts, antistatic floor coverings in medical establishments.

™ CH200 - having comparable structure and surface area it is more easily dispersed in rubber compounds and polymer composites as against ™ CH210 imparting finished goods sufficiently high level of electrical conductivity. ™ CH200 is used in the production of medical technics, rubber cloth, conductive screens of shaft and earthmoving cables.

™ CH200 - having comparable structure and surface area it is more easily dispersed in rubber compounds and polymer composites as against ™ CH210 imparting finished goods sufficiently high level of electrical conductivity. ™ CH200 is used in the production of medical technics, rubber cloth, conductive screens of shaft and earthmoving cables.

™ CH210 - As compared to standard conductive carbon black grades this type of grades has higher surface area and highly developed structure resulting in its excellent conductive properties at relatively low loadings. ™ CH210 can be used as reinforcing filler in conductive polymer materials (engineering plastic, cable jacket, etc), industrial rubber goods (conveyor belts, hoses for transmission of flammable liquids, etc.

™ CH210 - As compared to standard conductive carbon black grades this type of grades has higher surface area and highly developed structure resulting in its excellent conductive properties at relatively low loadings. ™ CH210 can be used as reinforcing filler in conductive polymer materials (engineering plastic, cable jacket, etc), industrial rubber goods (conveyor belts, hoses for transmission of flammable liquids, etc.

™ CH600 - is a high conductive grade with high parameters of surface area and structure. It is used for the production of chemical current sources and supercapacitors.

™ CH600 - is a high conductive grade with high parameters of surface area and structure. It is used for the production of chemical current sources and supercapacitors.

Specialty tire line:

™ H80 - differs from commodity tread carbon black grades by a moderately developed surface area in conjunction with a high level of structure. This grade imparts to the rubber compounds high wear resistance, as carbon black N100 and N200-series, and low heating up with deformation, which can be achieved with the N330.

™ H80 - differs from commodity tread carbon black grades by a moderately developed surface area in conjunction with a high level of structure. This grade imparts to the rubber compounds high wear resistance, as carbon black N100 and N200-series, and low heating up with deformation, which can be achieved with the N330.

™ H100 - is characterized by a developed structure, designed for better dispersibility of carbon black in rubber compounds and a maximum level of surface area among N300-series. High structure of ™ H100 allows increasing the dosage of carbon black to rubber compound within limits of extruded stream volumes. High level of surface area increases the wear resistance of the final product.

™ H100 - is characterized by a developed structure, designed for better dispersibility of carbon black in rubber compounds and a maximum level of surface area among N300-series. High structure of ™ H100 allows increasing the dosage of carbon black to rubber compound within limits of extruded stream volumes. High level of surface area increases the wear resistance of the final product.

Pigment line:

™ P110 - is a cost-efficient general purpose high structure pigment carbon black. Compared with other regular color pigment blacks it has better jetness with good dispersibility. ™ P110 is suitable for printing inks and variety of liquid inks. It provides high color intensity with excellent dispersibility in water-based flexographic inks. The product is used in decorative/industrial coverings, powder coatings, bonding agents, sealants, general purpose molding, agricultural film and coarse staple fiber.

™ P110 - is a cost-efficient general purpose high structure pigment carbon black. Compared with other regular color pigment blacks it has better jetness with good dispersibility. ™ P110 is suitable for printing inks and variety of liquid inks. It provides high color intensity with excellent dispersibility in water-based flexographic inks. The product is used in decorative/industrial coverings, powder coatings, bonding agents, sealants, general purpose molding, agricultural film and coarse staple fiber.

™ P140 - is designed for various plastic products, including plastic color concentrates. High surface area and structure allows for achieving excellent UV absorption. The product is characterized by high chemical and physical purity. ™ P140 is suitable for use in the production of wires, power and TV cables, coatings, agricultural films, and various fibers.

™ P140 - is designed for various plastic products, including plastic color concentrates. High surface area and structure allows for achieving excellent UV absorption. The product is characterized by high chemical and physical purity. ™ P140 is suitable for use in the production of wires, power and TV cables, coatings, agricultural films, and various fibers.

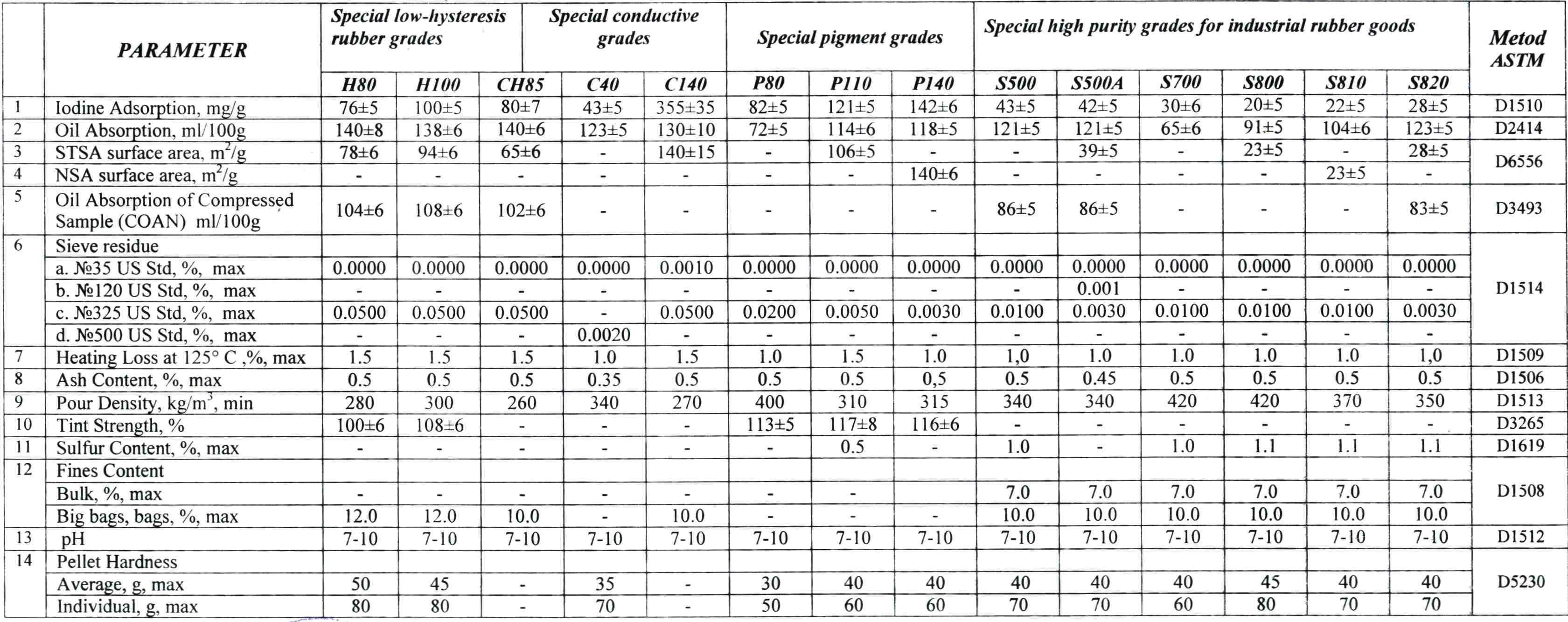

Technical specification :

|

|---|

product information page generated on: Thu Jul 31 16:02:45 CEST 2014